Abs Resin

(Total 10 Products)

-

-

-

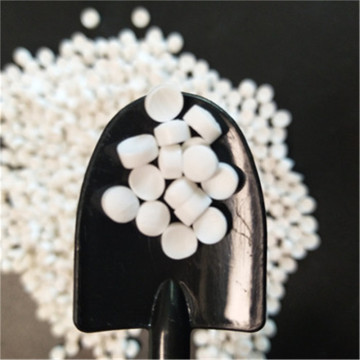

Plastic abs granules / abs resin, injection grade

Contact Now

-

-

-

-

Environmental Protection Granules Plastic Abs Resin

Contact Now

-

-

-

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance pvc resin and electrical properties. It is also easy to process, stable...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins pvc resin . It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties melamine powder. It is also easy to...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance,pvc resin heat resistance, low temperature resistance, chemical resistance and electrical pvc resin properties. It is also easy to process...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties melamine powder. It is also easy to process,...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties. It is also easy to process, stable in product...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties. It is also easy to process, stable in product...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties. It is also easy to process boric acid flakes...

-

Unit Price:2500~2680USD

Brand:LH

Min. Order:1 Ton

Model No:LH

Transportation:Ocean,Land,Air,Express

Packaging:25kg bag package

Supply Ability:100000ton per day

Place of Origin:CHINA

Productivity:100000TON PER DAY

Product Description: ABS resin is one of the five major synthetic resins. It is excellent in impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties. It is also easy to process, stable in product...

-

Unit Price:2350~2700USD

Brand:Lihao

Min. Order:1 Metric Ton

Model No:ABS Resin

Transportation:Ocean,Land,Express,Air

Packaging:25kg/pp Bag

Supply Ability:5000 MT/Month

Place of Origin:China

Productivity:5000MT/Month

Product Description Abs Resin is a kind of resin with very good comprehensive Rubber & Plastics > Plastic Raw Materials .Clear Abs Resin has higher impact strength and surface hardness in a wide temperature range Pvc Resin. Abs Resin Repair...

-

Unit Price:2350~2700USD

Brand:Lihao

Min. Order:1 Metric Ton

Model No:Abs Resin

Transportation:Ocean,Land,Express,Air

Packaging:25kg/pp Bag

Supply Ability:5000 MT/Month

Place of Origin:China

Productivity:5000MT/Month

Product Description Abs Resin is a kind of resin with very good comprehensive Rubber & Plastics . Abs Repair Resin has higher impact strength and surface hardness in a wide temperature range. Abs Plastic Resin is a kind of Plastic Raw...

Acrylonitrile butadiene styrene AKA Abs Resin (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 220 °F (104 °C). ABS is amorphous and therefore has no true melting point.

Abs Repair Resin is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene Rubber And Plastic. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. Abs Plastic Resin gives the plastic a shiny, impervious surface Ethylene-Vinyl Acetate, as well as hardness, rigidity, and improved processing ease. The polybutadiene, a rubbery substance, provides toughness and ductility at low temperatures Pvc Resin, at the cost of heat resistance and rigidity. For the majority of applications, ABS can be used between −20 and 80 °C (−4 and 176 °F), as its mechanical properties vary with temperature. Abs Casting Resin properties are created by rubber toughening, where fine particles of elastomer are distributed throughout the rigid matrix.